Many activities in factories, event centers, hotels, construction projects and other industries require some kind of set-up—or “predecessor”–before the activity can occur.

But not all predecessors are the same. Most predecessors need to finish any time before the actual activity starts. For example, a meeting room needs tables and chairs to be set up at some time before the meeting occurs. Similarly, for a construction project, concrete forms must be set at some time before the concrete is poured. Or a piece of equipment must be cleaned at some time before it is used again. These are traditional predecessor relationships and, as you may expect, many scheduling systems can handle them.

However, another type of predecessor is one in which the preceding activity must occur immediately before the scheduled activity. Examples of this type include configuring a machine so that it can make the right part, or administering anesthesia before a medical procedure begins, or loading paper into a printer just before the print run starts. We’ll call these “immediate predecessors.”

To properly model an immediate predecessor of this type, it would help to incorporate this step into the activity itself so other activities cannot be inserted between them. This approach requires capabilities that some scheduling systems do not have:

- The ability to require different resources within the same activity;

- The ability to require resources intermittently within the activity; and

- The ability to require different numbers of resources for different intervals within the activity.

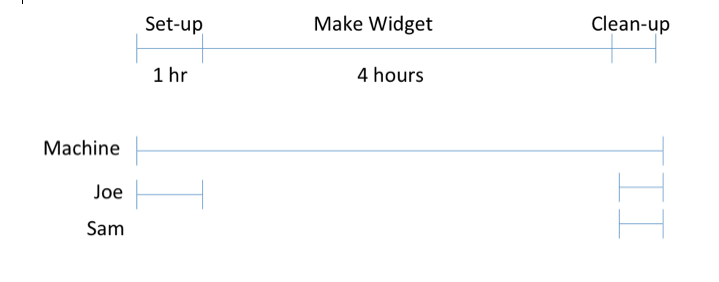

Here’s how it works: Suppose we are scheduling a “Make Widget” activity that is four hours long. It takes an hour to set up the activity, and 45 minutes to clean up and shut down the machine. We want to define an activity that is five hours and 45 minutes long, and it will require Joe to do the set-up and both Joe and Sam to do the clean-up. Here’s the diagram:

Notice the three requirements stated above are required in order to describe the immediate predecessor and successor relationships in this situation. We have seen these requirements so often that we can claim with confidence that they are the norm not the exception.

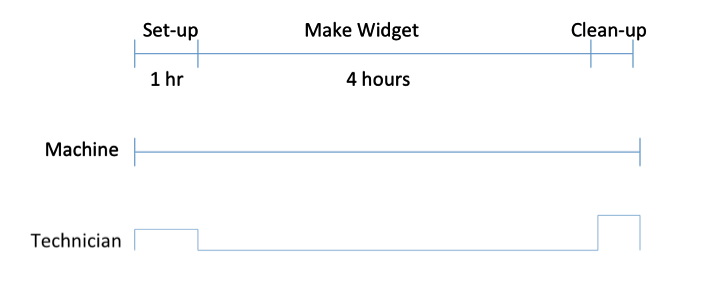

What if the requirement for the set-up and the clean-up didn’t require specific people, but rather any technicians from a pool of equivalently-skilled workers? Now the diagram might look like this:

If you have a scheduling situation that requires immediate predecessors and successors, look for a system that satisfies the three requirements listed above. Only then, will your system be able to set a schedule that is actually realistic and doable.

Comments? Questions? Let’s talk about it.